PROCESSING OF GLASS REINFORCED THERMOPLASTICS

The addition of glass fibers to thermoplastics changes the processing guidelines for these materials. The following discussion is aimed at enabling you to mold the strongest parts possible by preventing fiber length attrition below the critical length .

1. Molding machine considerations

In-line reciprocating screw injection molding machines

work best for molding reinforced composites. Plunger type machines do not

provide uniform melt consistency or the same shot to shot accuracy that

a screw type machine provides.

The injection molder should be capable of injection

at pressures of at least 20,000 psi. An injection speed control valve is

desirable even though the fastest possible injection speed should be used

except where tooling limitations exist. Closed-loop control of barrel and

nozzle temperatures is also desirable.

General purpose type screws with compression ratios

of less than 3:1 are acceptable but lower compression screws help preserve

fiber integrity and reduce shear heating of the base resin. Screws with

a 2.0-2.5:1 compression ratio, and a minimum 18:1 L/D ratio are recommended.

A free flow non-return valve should be employed because it allows non restrictive

flow and lessens fiber damage. Positive shut-off valves should be avoided.

While injection pressures as high as 20,000 psi may

be necessary, tool life can be extended by using the lowest possible pressure

for each job. This also prevents flashing. A clamping force of 5 to 10

tons/in, of projected area of the part should be available; that is. 50

to 100% more clamping tonnage is necessary for a reinforced thermoplastic

than for a regular resin.

As with other molding jobs. 50-75% of the machine's

rated barrel capacity should be used.

2. What your auxiliary needs

will be

The essential material handling techniques for the

base resins also apply to the reinforced counterparts.

While the resin is packaged dry and in moisture-resistant

containers, hygroscopic materials (e.g., nylons, polycarbonates, polyesters,

etc. ) should be dried before molding with either a dehumidifying oven

or hopper. Since hot air has a higher moisture capacity, it is possible

to actually introduce moisture to a resin by using a circulating hot-air

oven. To prevent this, use dehumidifying equipment. If an oven is used,

spread the molding compound on trays at a depth of 1/2 in. or less and

dry at least four hours at the recommended temperature. (Oven or hopper

should be capable of maintaining a temperature of at least 250°F ±

5°F.)

It is occasionally necessary to dry even non-hygroscopic

resins to eliminate surface blemishes caused by moisture which has condensed

onto pellet surface.

Mold temperatures for reinforced resins will generally

be higher than for the non reinforced ones. Higher mold temperatures will

promote flow and give a better surface finish. A slightly higher mold temperature

will not increase cycle time. Standard mold temperature control equipment

is satisfactory.

The choice of temperature controllers will depend

on the resin being molded. For instance, oil or electric cartridge heaters

are needed when heating a mold for PEEK or PES where temperatures of 350°F

and 300°F, respectively, should be used. It's preferable to have independent

temperature control for each mold plate. This gives flexibility, especially

in long cores where it is often desirable to maintain each core at different

temperatures from the cavity.

When runner systems and rejected parts are reground,

any conventional scrap grinder may be used. Use a 3/8 in. to 1/4 in. screen.

As a rule of thumb, a maximum of 20% regrind can be blended with virgin

material with no appreciable loss of properties or color. If end use properties

are important or critical part tolerances are required, the use of any

regrind should be fully qualified prior to production. Be sure to keep

regrind free of contamination and dry before recycling. Blend regrind with

virgin material before adding it to hopper dryer.

3. Choosing a mold material

For extended production runs, hardened tool steels

are recommended. Select a mold steel that will provide the best combination

of abrasion and corrosion protection for the type of compound to be run.

Machinability should also be considered if a highly polished surface is

needed. Electroless nickel or chrome plating the mold surfaces will help

improve surface hardness, extend tool life, and provide additional corrosion

protection.

Aluminum, epoxy or P-20 steel materials are satisfactory

for prototype work.

Accelerated tool wear has sometimes been associated

with glass-reinforced thermoplastics. Few have been able to document any

case of excessive tool wear where proper mold design and processing conditions

were used with pre-dispersed glass fiber reinforced thermoplastic compounds.

Examples of conditions that can undesirably increase tool wear include

using un-dispersed glass fibers, excessively small gates, or use of soft

tool steels such as P-20.

4. Mold design factors

A Nozzle having an inside dia. of 7/16 to 1/2 in.

is recommended for most glass-reinforced thermoplastics. Exit orifice should

be 1/4 in. and the land should have a reverse taper of two to three degrees.

A reverse taper nozzle will provide a defined sprue break and reduce drooling

with low viscosity compounds.

A positive shutoff valve should be used only when

a low-viscosity resin like nylon is being molded at high melt temperatures

or when you are molding in a vertical machine.

The sprue bushing should be as short as possible and

have a taper of at least three degrees. The orifice should be slightly

larger than nozzle; that is, when using a 1/4 in. nozzle, sprue bushing

should have an orifice of 7/32 in. Of course, the radius of sprue bushing

and nozzle must match. Mismatch of these radii may cause sprue to hang

up in the mold.

The shortest possible runner systems should be used

and it should be polished to maximize flow.

In multi-cavity molds, where close part tolerances

are required, a balanced runner system is extremely important to achieve

part-to-part uniformity.

Size and location of gate (or gates) are the most

important factors in achieving a good molded part. General practice is

to gate into the thickest section of a part to minimize sinks or voids;

however, if surface finish is critical on a thin section, open the gate

into that section to maximize gloss.

In general, avoid a gate which directs melt against

a cavity wall or core pin because a gate of this type fractures the glass

fibers.

The number of gates used should be kept to the absolute

minimum necessary to fill the part in order to avoid weld lines that weaken

parts. If more filling capacity is necessary, enlarge the gate rather than

add additional ones.

The most widely used gate should be either full round

or rectangle. Specialized gates, such as diaphragm or flash gates, are

useful for special applications. The size of a round or rectangular gate

should be from two-thirds to the full width of the cavity wall. One advantage

of a rectangular gate is that, if more filling capacity is needed, gate

width may be widened without affecting freeze-off time.

Don t use small pinhole gates. A round gate should

not be less than 0.040 in. A good rule of thumb to follow is the larger

the molded part, the larger should be the gate except that the dia. of

a round gate should not exceed part's wall thickness.

The transition from runner to gate should be a blend

of gentle tapers rather than sharp angles to maintain highest possible

physical properties.

To keep pressure drop through the gates to a minimum,

keep lands short. Land lengths should be from 0.020 to 0.040 in.

Good venting of the cavity is essential for rapid,

uniform fill. For glass fiber reinforced resins which are low in viscosity

(like nylon), vents should be 0.001 by 0.025 in. wide. For a highly viscous

resin like polysulfone, vents of 0.004 by 0.200 in. wide can be used. The

most strategic locations for the vents are wherever air will be trapped

due to resin flow, i.e., at weld lines and the end of cavities. Vents should

be spaced about one inch apart along mold parting lines. Loose fitting

knock-out pins will also serve as vents. As for knock-out pins, large ones

or stripper plates should be used.

5. Part design factors

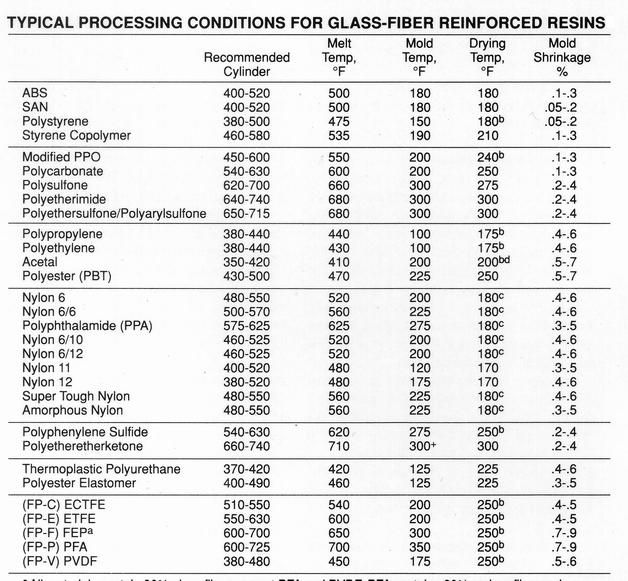

Typical shrinkage of glass fiber reinforced resin

will be one-third to one-half that of the non reinforced resin. Typical

shrinkage values for a variety of resins reinforced with 30% glass fibers

are given in the Table.

It is important to start with a prototype tool to

determine exact shrinkages, particularly to determine shrinkages of complex

parts which must be held to tight tolerances. Parts which have drastic

variations in wall thickness or which are molded of resins exhibiting anisotropic

shrinkages should be prototyped.

A non reinforced anisotropic resin (e.g., unfilled

nylon) will shrink more in direction of flow than in the axis transverse

to flow; however, when fiber glass is added to resin, glass fibers tend

to orient in flow direction; this limits shrinkage in flow direction. The

result: Glass fiber reinforced resins will shrink more along the axis transverse

to flow than along the axis of material flow.

Due to the lower shrinkage of reinforced resins, more

draft should be designed into the part to facilitate ejection from mold.

An angle of two to three degrees is recommended for core pins and cavity

walls.

Wherever possible, avoid designing undercuts which must be stripped from a mold.

6. Pointers on molding compounds

Typical start up processing conditions are shown on

the table. Optimum parameters should be developed for each job from these

initial settings.

Minimal back pressure (25-50 psi), and low screw rpm

(30-60) should be utilized to avoid excessive fiber breakage. A fast injection

rate will promote the best surface finish in fiber reinforced materials

but may cause property variation in lubricated or statically dissipative

composites due to shear effects on the additives. Cavities should be filled

as rapidly as possible to minimize fiber orientation and enhance weld-line

integrity. Properties of reinforced resins are optimized by packing the

part as much as possible.

Higher than average mold temperatures should be used

to maximize flow and obtain a good surface finish. A hotter mold can be

maintained for a reinforced resin without lengthening cycle.

7. Processing of Long Fiber Composites

Long fiber resins can be easily processed on conventional

molding equipment. The excellent resin impregnation of the fibers in these

long glass compounds has shown that no increase in screw, barrel, or tool

wear should be expected when compared to short glass fiber counterparts.

In order to maintain the long fiber lengths that give

these composites their strength and impact capabilities, the following

processing and design parameters are suggested.

"General purpose" screws are satisfactory for these

composites. "Nylon" type screws. or those with compression rations higher

than 3:1 should be avoided.

Screw speeds of 30-60 rpm and back pressure of 10-75

psi will minimize fiber breakage also. A minimum gate size of 0.080" is

suggested. Edge gates or subgates smaller than this can cause severe fiber

damage.

A free flow non-return valve (screw tips) should be

employed because it allows for non-restrictive flow and less fiber damage.

Melt temperatures 20-40°F higher for long fiber

than for short fiber composites will help preserve fiber lengths by allowing

a less viscous melt to help lubricate the fibers. A reverse" (higher rear

zone) profile can be utilized to help achieve quicker melting.